0

+

National patent

National patent

Working Experience in PowerElectronics R&D

R&D personnel

Hi-Tech Talent

Cooling Method: Air-cooled uses fans/convection; liquid-cooled circulates coolant.

Application: Air-cooled for small/medium systems; liquid-cooled for high-power/industrial uses.

Efficiency: Liquid cooling offers higher heat dissipation and stability.

Design: Liquid-cooled systems are more complex and integrated.

Cost: Air-cooled has lower initial cost; liquid-cooled requires higher investment but less maintenance.

Power Use: Liquid cooling consumes more energy for pumps/cooling units.

Effective cooling technology is essential for maintaining high inverter efficiency, ensuring optimal energy conversion and system reliability in both air-cooled and liquid-cooled applications.

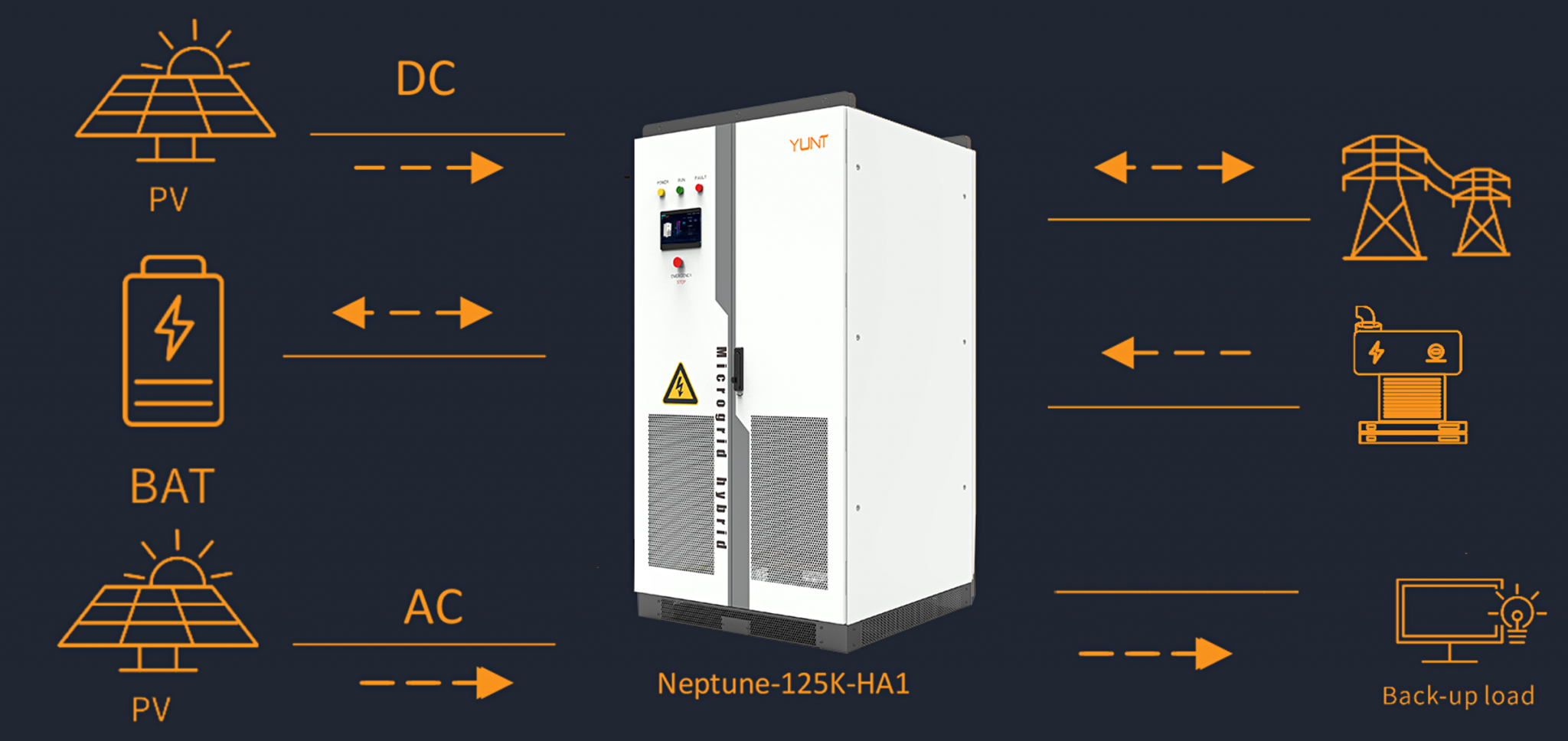

Hybrid inverters play a vital role in modern energy storage systems (ESS) by efficiently integrating renewable generation with battery storage. They enable seamless energy management, improve self-consumption of solar power, support both on-grid and off-grid applications, and allow scalable system expansion. However, challenges include higher initial costs, system integration complexity, battery lifespan concerns, and limitations in high-power industrial settings. Despite these issues, hybrid inverters remain a key solution for flexible and efficient energy utilization, supporting the transition toward resilient and sustainable power systems.

Air-cooled inverters rely on airflow for heat dissipation and have relatively weak environmental adaptability. They are prone to overheating in high temperatures, and their cooling systems can easily become clogged in dusty environments, requiring frequent maintenance. However, they are suitable for temperate regions.

Liquid-cooled inverters use a sealed liquid cooling cycle, which offers high heat dissipation efficiency. They perform well in high temperatures, are dustproof, corrosion-resistant, and ideal for extreme environments such as deserts, coastal areas, or industrial zones. Maintenance mainly involves periodic coolant checks, making it more convenient.

Hi there! We are a commercial and industrial energy storage solutions provider. If you have any needs, I’m more than happy to assist. Looking forward to connecting with you!

+86 13392865964

+86 075523592426

Factory Building 1 No. 15 Tianbao Road,Bao'an District, Shenzhen city,Guangdong Province China

Whether you are interested in our energy storage products, solutions, or a potential partnership, we’re here to help. Feel free to reach out — our international sales team will respond promptly.